Ensuring Your Belts Go the Distance

How to Achieve Material-Chemical Compatibility During Cleaning to Extend Belt Life

- Insights

- May 8, 2023

In a previous article, we covered the key factors in choosing the right belt material for food conveyors. Specifically, our experts considered what conditions belts would be subjected to during production.

But what about during cleaning and sanitation?

Choosing a belt material based on your product, application, and environment is just the first part of the equation. Once belts are installed and running, you could easily damage the right belt material with the wrong cleaning agents.

If that doesn’t sound so bad, consider this: using chemicals—or chemical concentrations—that are incompatible with your conveyor belt material can pose the worst kinds of risks for your processing line. These include foreign material contamination, scrapped product, unscheduled downtime, increased costs due to more frequent belt replacements, and even a recall.

What can you do?

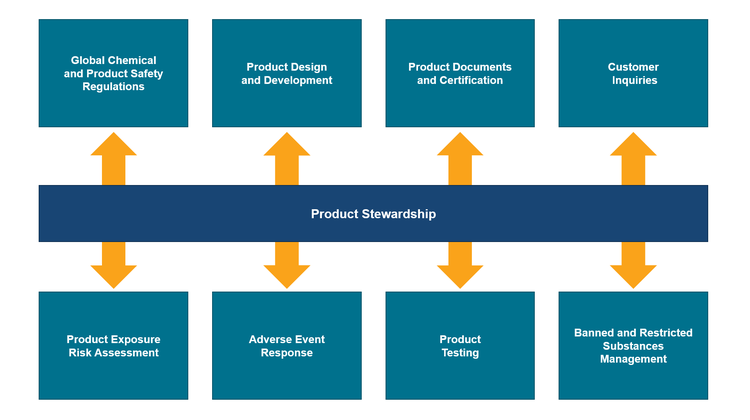

To find out, we turned to the experts in Product Stewardship, a highly specialized group at Laitram* that offers free information, guidance, and services that our customers may not know about.

Laitram’s Product Stewardship department includes a unique group of specialists with a wide range of responsibilities, including chemical testing and compatibility.

Communicate with Sanitation

We know from field experience and conversations with our customers that cleaning and sanitation are largely outsourced to third-party companies that specialize in large food-processing facilities. If your plant brings in an outside cleaning crew, make sure you’re regularly communicating with them.

“In many instances, there’s a disconnect between what plant management thinks they’re doing and what the sanitors are actually doing,” says Evan McSpadden, Chemical Specialist in Product Stewardship at Laitram. “For example, we’ve seen cases where sanitation crew members have changed the chemical concentration they use without the processor knowing.”

There’s an easy fix: Talk with your third-party sanitation company regularly. Ask them what cleaning chemicals and concentrations they’re using and make sure those are compatible with your critical, direct-food-contact belts.

Intralox Team Tip: If you take proper care to ensure compatibility between cleaning agents and belt materials, chemical resistance can far exceed usable belt life.

Understand Why More Isn’t Always Better

Sanitors often misuse or overuse chemicals to clean belts quickly. They may even believe that somehow doing “more” cleans belts better and faster. But this can have detrimental effects on belts, especially those made from less chemically resistant materials. Here are some examples where more isn’t necessarily better for the health of your belts:

- Concentration: It’s best to use chemicals at their lowest concentrations that are most effective for the application.

- Temperature: Every 10°C the chemical temperature is increased for cleaning essentially doubles its effect, leading to a higher concentration.

- Acid Stacking: Using multiple acid-containing chemicals during one application isn’t always effective and can cause structural and equipment damage.

- Alternating: Regularly rotating sanitation chemicals may not be necessary or beneficial.

Make sure your facility has good sanitation standard operating procedures (SSOPs) in place and your crew is consistently following them. That’s a significant step you can take toward prolonging the life of your belts and ultimately keeping your product safe.

Chemical suppliers aren’t experts in compatibility with conveyor belts. They focus on how their chemicals affect microorganisms. We focus on how cleaning chemicals interact with common belting materials to help processors extend usable belt life.

Chemical Specialist in Product Stewardship at Laitram

Know What to Look For

Here are some common, visible indicators that a belt material is incompatible with a cleaning chemical:

- Chalking (whitening) of the belt surface

- Cracking

- Pitting

- Delamination

- Blistering

- Discoloration

- Swelling

- Embrittlement

Years ago, a large meat processing company began noticing cracks on their belts. After sending us a piece of their belting to test, we discovered phosphoric acid—a common cleaning chemical—was all over the sample.

“The customer’s acetal belts were incompatible with the chemical their cleaning and sanitation crew was using,” says Gloria Bowman, Manager of Product Stewardship at Laitram. “That case drove my team to develop a one-page chemical compatibility guide for meat, poultry, seafood processors.”

Chemical Compatibility Guidelines for Meat, Poultry, Seafood (MPS)

Here’s a handy chart you can download, share, and use in your MPS plant to get a general idea of how compatible frequently used belt materials are with common cleaning chemicals or sanitizers.

Cleaning is not the enemy of production.

Processors are always looking to increase production time and decrease the time it takes to clean between processing. It makes sense: one makes them money, the other costs them money.

But racing to cut cleaning time by overusing or misusing chemicals to fight foodborne pathogens can come with a heavy price.

“If crews are allowed a little more time to clean properly,” says McSpadden, “they could reduce chemical usage, cut downtime needed for quality inspections and rework, minimize belt damage, decrease foreign material contamination risk, and extend belt life.”

*Intralox is a subsidiary of Laitram.

For questions about chemical compatibility or to send us a belt sample for testing, contact Intralox Technical Support.