Conveyance systems for case package handling

Case and packaging equipment manufacturers worldwide partner with Intralox because we help them win projects. How? With innovative technology, best-in-class service, and deep industry and equipment expertise.

Our case package handling specialists can help you:

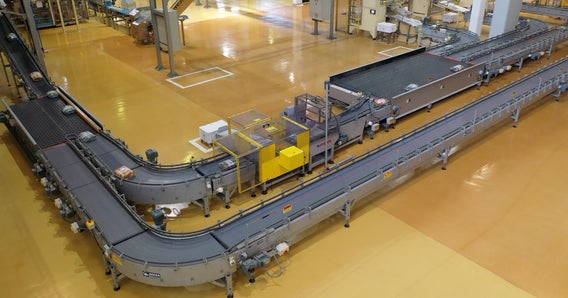

- Optimize line layouts

- Standardize your belts, equipment, and components

- Design and develop conveyor projects with unmatched support—on-site, direct, or through collaborative digital tools like CalcLab

Solutions for case package handling

Where can Intralox make the difference for you?

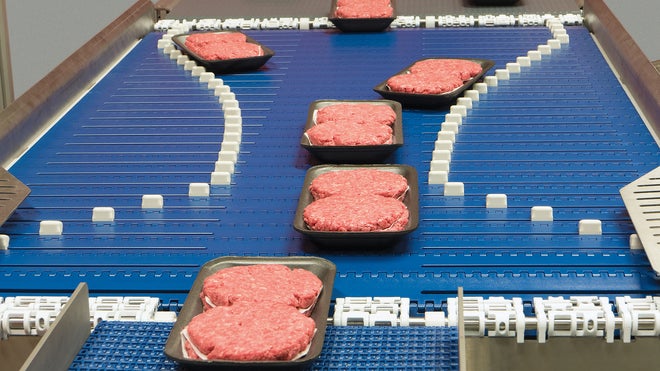

Packaging BeltingRisk-free, future-ready, proven conveyance belting solutions

Help end users launch products in new package formats, upgrade existing plants, handle new and existing products on the same line, and maintain high-quality product conveyance with Intralox’s innovative belting solutions.

The Benefits of Intralox’s packaging belting portfolio:

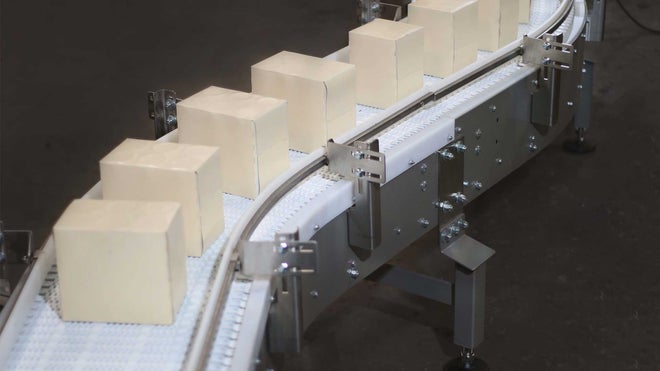

- Only three belt series for a complete conveyor system

- Eliminate dead plates with a 0.75-in (19-mm) nose-roller that's compatible for straight-run, accumulation, and radius belts

- Same-day shipping for the most common belts in standard widths (most markets)

Producing Results

36

hours reduced downtime annually

120

ft/year belt replacement savings

9

months payback period

* Data varies based on application and customer environment

Insights and Results

Case package handling success with Intralox solutions