Conveyor belts and equipment for EV battery manufacturing

Intralox’s future-ready, innovative solutions scale battery production and increase speed to market in your electric vehicle (EV) plants, offering you increased productivity alongside reduced costs.

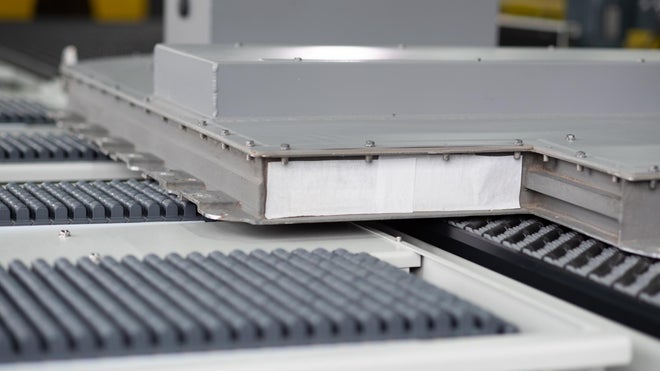

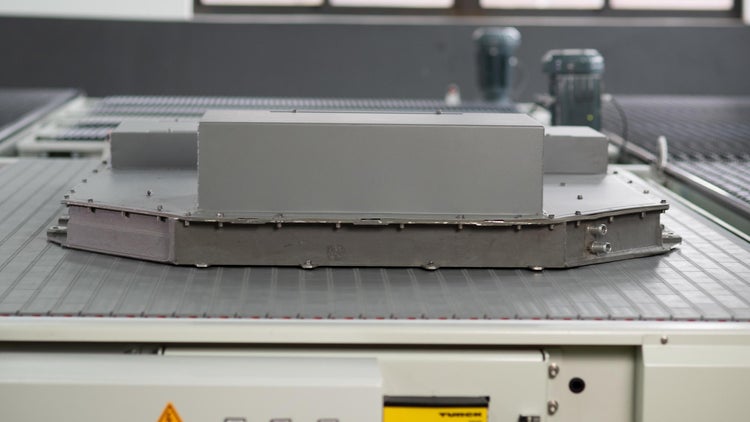

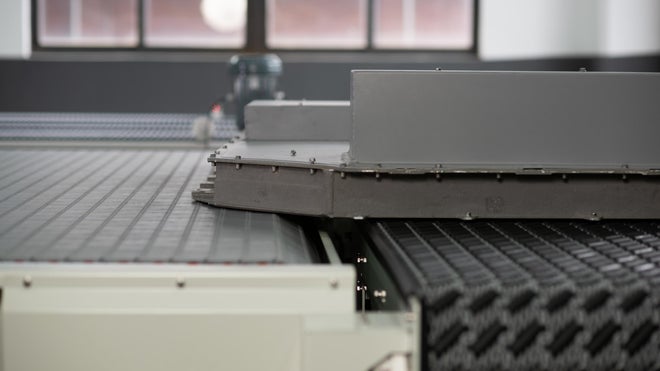

Our technology offers gentle, touchless handling of delicate, high-voltage lithium-ion battery packs and modules, reducing risk and increasing throughput. Its high roller density accommodates large variations in product size and weight, keeping you ready for the future. Combine that with its resilience against chemical attack from common battery fluids, and you’ve got an EV conveyance solution that offers drastically reduced maintenance and costs compared to traditional technologies.

Solutions for EV battery manufacturing

Where can Intralox make the difference for you?

90-Degree TransfersMaintain battery orientation at the highest possible throughputs

Our 90-degree transfer solutions more reliably maintain product orientation and higher throughput than any alternative technology. With limited moving parts and controls required, they’re easy to install and offer 50% lower maintenance costs—along with enhanced safety and long service life. Plus, their high roller density gently handles a large variety of battery sizes and weights.

Belt and equipment solutions for this area include ARB equipment (DARB S4500 or ARB S400) and radius conveyor belts (S2100 ZERO TANGENT Radius Flat Top belting).

Benefits of Intralox's 90-Degree Transfer solutions for EV battery production:

- High roller density can accommodate large variations in product size

- Higher throughput than pop-up systems at same belt speed

- Product aligned at outfeed

- Lower takt time due to continuous movement

- No controls or compressed air required

- Reduces floor space usage and improves layout flexibility

Intralox’s DARB [Transfer] S4500 has been in use by our company for about two years. The equipment is running steadily and has not required any maintenance. Its working principle is ingenious, and we give it a high evaluation. We hope to have the opportunity to collaborate again in the future.

General Assembly Equipment Manager

Global EV Manufacturer

Inventing the Future of EV Battery Conveyance

Intralox’s future-ready, innovative solutions scale battery production and increase speed to market in your electric vehicle (EV) plants.

Insights and Results

EV manufacturers find success with Intralox solutions