Conveyor belts and equipment for the dairy industry

For many years, we’ve worked closely with dairy customers around the world to develop optimized conveyance solutions backed by unmatched service and support. Whatever you produce—butter, cheese, ice cream, yogurt, or any other milk-based product—our deep industry experience and expertise will help you operate excellently at every stage.

Intralox’s conveyor belt and equipment solutions for the dairy industry help you:

- Increase throughput and reduce product waste

- Reduce maintenance and sanitation costs

- Enhance product-handling flexibility

- Improve food safety and hygiene

Dairy processing areas

Where can Intralox make the difference for you?

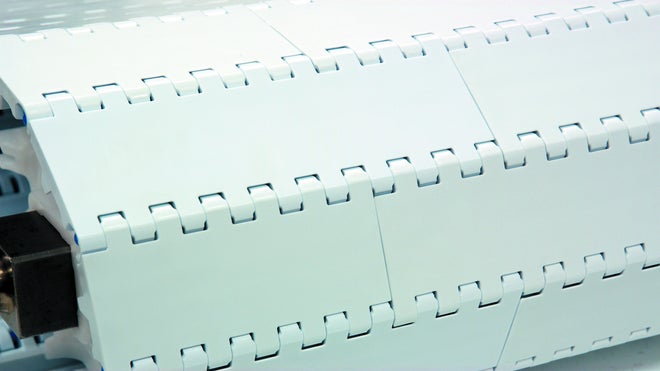

Primary ProcessingProtect your line, profits, and brand with Intralox FoodSafe

Pairing the right conveyor belt with effective sanitation procedures is critical to succeeding in early production stages.

For primary processes like butter making or cheese block forming, the wrong conveyor belt can pose unnecessary risks. These include mistracking, belt flipping, edge fraying, and foreign material contamination (FMC).

Intralox® FoodSafe™ is a comprehensive system of products, services, and training designed to help you achieve the best possible outcomes in uptime, throughput, and food safety. For primary processing applications, our dairy industry and food safety experts can help you optimize belts, materials, processes, and designs, allowing you to:

- Maximize belt life and performance

- Increase safeguards with detectable materials

- Maintain belt strength and durability in high-chemical-exposure applications

- Mitigate FMC concerns

- Continuously monitor belt performance and improve your sanitation programs

Intralox’s new ThermoDrive belt has made sanitation easier and less labor intensive while saving us 40 minutes per day in cleaning time. In addition, our product releases from the ThermoDrive belt more easily. I would recommend ThermoDrive belting to any dairy facility hoping to increase the cleanability and reliability of its belts.

Claude LaPolice

Maintenance Supervisor at La Coop Agrilait

Insights and Results

Dairy producers find success with Intralox solutions