Candia Enhances Sorting Line with ARB Technology

Case StudyCandia

Products

ARB Equipment

Industries

Dairy

At its plant in Clermont Ferrand, France, Candia produces 52,000 tons of butter each year for retail, food-service, and food-processing customers throughout Europe. The butter is produced and packaged in multiple formats that are then packaged in cardboard boxes of various sizes.

The plant was planning to build a new palletizing zone—composed of nine conveying lines and three robots—located one floor lower than its production and packaging operations. Candia needed a system flexible enough to handle its variety of products, but that also eliminated the risk of product jams, offered improved safety, saved floor space, and reduced maintenance and labor costs.

The Intralox ARB solution fit all our requirements while providing a more aesthetic design with no visible moving parts.

Mr. Helder Dias

Candia Director of Operations and Technical Project Manager

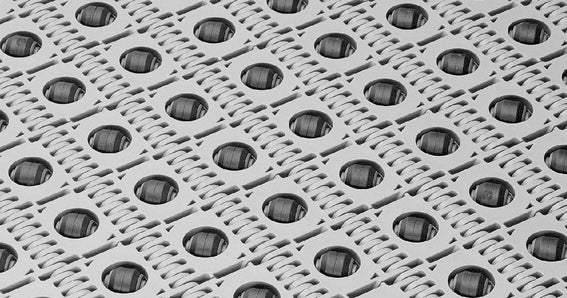

Candia installed a new palletizing system that utilized an Intralox DARB Sorter S400, which was used to sort and feed products to the robots. Candia chose to partner with Intralox because Intralox Activated Roller Belt (ARB) technology fit all of its project goals, especially safety. ARB equipment uses no external moving parts (such as pusher arms) and is quieter than the alternative technologies that Candia had considered.

The partnership between Intralox and Candia, as well as Candia’s palletizer OEM and preferred integrator, proved seamless and mutually beneficial. Five years after installation, the DARB Sorter has improved operator safety, and eliminated jams and line stops while requiring zero unscheduled maintenance.