Ananda Group and Intralox Set New Benchmarks in India's Shrimp Industry

Case StudyAnanda Group

Products

Modular Plastic Belting, ThermoDrive Belting

Industries

Fish and Seafood

Customer Objectives

Ananda Group is a leading food processor in India with a strong presence in the shrimp industry. From hatcheries to further processing, the company is involved in several parts of the supply chain and provides their product to many of the world’s largest consumer markets and brands.

When the company needed to upgrade the hygienic design and product conveyance at their three shrimp processing facilities in Andhra Pradesh, they turned to Intralox.

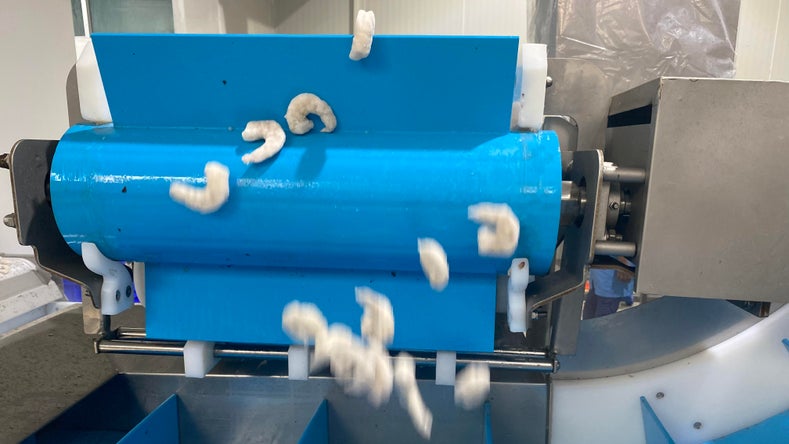

Existing conveyors were difficult to access during sanitation, requiring excessive amounts of water and labor for cleaning. Several conveyor belts needed frequent replacing, while others contributed to shrimp tail breakage and other product yield and loss issues.

Intralox Execution

Intralox took a consultative approach to help Ananda solve these challenges and modernize their facilities.

Commercial Food Sanitation (CFS), an Intralox company, performed detailed audits at each plant. CFS submitted tailored recommendations for facility and conveyor design modifications to solve some of Ananda’s key hygiene issues. In addition, CFS provided training on wet sanitation and hygienic design, which included interactive exercises to engage and educate plant personnel.

To address Ananda’s belt issues, Intralox recommended upgraded modular plastic belting (MPB) for key applications including the infeed to hardener, spiral, and freezer conveyors. For setting and incline conveyors, Intralox ThermoDrive belting was proposed due to its hygienic, closed flat top surface and superior cleanability.

The recommendations, belting, and support from Intralox have significantly elevated the level of conveyance at Ananda’s shrimp processing facilities. We continue to partner with Intralox and CFS to help us match global best practices for hygienic food processing so we can supply customers with safe, high-quality product.

Anand Ramesh Varma

Ananda Group Director

Intralox’s conveyor belts proved so successful that Ananda upgraded several additional conveyors at each critical application in their facilities.

At Ananda’s request, Intralox also collaborated with their OEM to optimize the hygienic design of their conveyors and facilitate easier cleaning. Intralox engineers worked closely with plant staff to ensure all conveyor belt upgrades were implemented smoothly with no production interruptions.

Results

Since partnering with Intralox in 2019, Ananda Group’s shrimp processing plants have seen significant improvement in the operation and cleanability of their critical conveyors. Water consumption for cleaning has declined 50% and sanitation time has been reduced by 47%. Product yield has improved, and shrimp tail breakage has been virtually eliminated.

Together with Intralox and CFS, Ananda Group continues to improve their standards and processes, setting new benchmarks in efficient, hygienic processing for India’s shrimp industry.