Intralox Reduces Hygiene Product Manufacturer’s Annual Labor Costs by $288,000 and Increases Production Capacity by 30%

Case StudyGlobal Hygiene Product Manufacturer

Products

ARB Equipment, Modular Plastic Belting

Industries

Consumer Goods

Customer Objectives

A global hygiene product manufacturer was using manual labor to accumulate, switch, and palletize their products in a European diaper plant. Their process was for laborers to manually hold bundles back until workers down the line were ready to make them into cases. Products were also being sorted and merged by hand, and someone worked at the end of the lines to manually palletize them. The plant’s goal was to implement partial automation to decrease labor costs and future-proof for robotic palletizing, but they were unsure of how to achieve the goal given their complex and inaccessible line layouts.

Intralox Execution

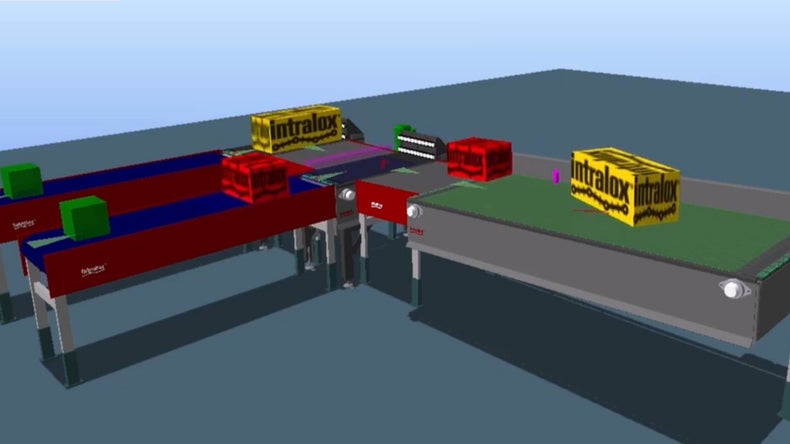

After considering radius belting from a competitor whose conveyors they used in the past, the manufacturer chose Intralox to completely optimize their lines. Our experts worked with them directly to create an entirely new layout, which includes our Dual-Stacked Angled Roller Belt (DARB) technology alongside other Intralox belting and equipment for a comprehensive solution.

In addition to organizing the layout into a more compact footprint, we installed a Series 1000 High Density Insert Roller belt, which allows for bundle accumulation while a worker prepares and packs cases. We also installed a DARB Sorter S4500 (1:2) to automate the sortation process, along with two passives for merging and an Activated Roller Belt (ARB) Case Turner S400 in front of the palletizer. The manufacturer opted to retain manual palletizing, but the lines now offer the flexibility to add a robotic palletizer in the future.

Results

The plant’s optimized layout created space for seven potential new lines. The automation added to their simplified lines reduced labor costs by $1,000 per shift, which across the eight lines we optimized adds up to a monthly savings of $24,000—or $288,000 per year. On top of that, throughput has risen from 20–25 to 30–35 packages per minute, an increase in production capacity averaging 30%. Their goal is to optimize more lines in the future with Intralox technologies.