Salumificio Mec Palmieri Eliminates Belt Edge Breakage and FMC with Intralox Heavy-Duty Edge Belting in PK

Case StudySalumficio Mec Palmieri

Products

Modular Plastic Belting

Industries

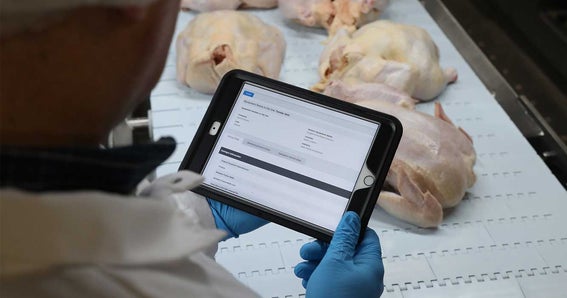

Meat and Poultry

Solutions

Intralox FoodSafe

Customer Objectives

Salumificio Mec Palmieri, a leading producer of premium cured meats, was concerned about the potential foreign material contamination (FMC) risk that the belt on their frozen meat block elevator presented. The belt had been regularly breaking at the edges from the time of installation. In fact, Mec Palmieri’s Quality department reported weekly that they’d discovered broken belt pieces on the floor under the elevator. Though no broken belting had ever been found in the product itself, the FMC risk was so significant that Mec Palmieri decided to be proactive. After all, a single FMC occurrence could cost them multiple days’ production, or €120,000 – €150,000 worth of product per day.

Intralox Execution

Having previously collaborated with Intralox in other areas of their facility, Mec Palmieri contacted us for immediate assistance in identifying solutions to minimize FMC risk in their elevator. Our Intralox FoodSafe team recommended that Mec Palmieri first identify and fix any catchpoints on their belt frame. We then retrofitted their system with our Series 800 Open Hinge Flat Top belt with Heavy-Duty Edge in blue PK (Polyketone), a fault-tolerant belt with reinforced side edges.

Our elevator belt has gone from requiring constant oversight to being one we can pretty much forget. We’re so appreciative of Intralox’s consultation and support in improving our operations and safeguarding our product quality and brand reputation.

Giuliano Ghelli

Plant Director at Salumficio Mec Palmieri

Intralox PK was developed specifically for direct food–contact applications. This robust material reduces nonmechanical belt breakage and FMC risk, and is more impact, chemical, and abrasion resistant than acetal. Further, the Heavy-Duty Edge belt features a closed flush belt edge that minimizes catchpoints and thicker links that reduce wear while maximizing belt life.

Results

The Intralox® FoodSafe™ approach’s results far exceeded Mec Palmieri’s expectations. Since the new belt was installed in October 2022, Mec Palmieri has had zero edge module breakage. This has eliminated belt breakage–related contamination risk and allowed them to continue meeting their renowned high standards. Plus, the new belt is much easier to clean due to PK’s superior release properties, higher chemical resistance to proper detergents, and lack of broken modules. Mec Palmieri estimates a 75% reduction in the time required to properly clean and sanitize their elevator.