Are Your Customers Safe from Microbial Issues?

How to avoid product recalls and protect your brand

- Insights

- February 21, 2025

In the second half of 2024 alone, multiple high-profile contaminant outbreaks shook the food industry—and challenged consumers’ trust in it.

These outbreaks were reportedly linked to hundreds of illnesses and more than ten deaths. The product recalls associated with these outbreaks are measured in millions of pounds.

The implications of these outcomes are scary for any consumer or company in our global food supply chain. Our food system’s increased complexity enables these outbreaks—and news of them—to spread faster than ever. And with reports from Axios in 2024 that food recalls have continued to rise since the pandemic, that fast-spreading harm can seem inevitable.

Rather than discourage action, though, this should underscore the importance of preventing the contamination you can. Microbial contamination in our global food supply poses significant risks both to your consumers’ health and your brand’s reputation.

Because Intralox plays an important role in moving the world’s food supply, we understand these risks deeply—and how to begin mitigating them. We’ve worked continuously—often alongside you in your facilities—to develop technologies and services that improve food safety, globally.

Here’s how we can help.

Best Practices

While you may not be able to control outbreaks in your suppliers’ fields, you can equip your team with the skills and knowledge to stay ahead of the food industry’s evolving best practices. In fact, it’s essential to do so.

“Listeria can get into little crevices, into this machinery, and if not cleaned properly, they create a biofilm,” Bill Marler, a food safety lawyer at Marler Clark, shared on his blog. “That biofilm will slough off every once in a while, and that Listeria will get into the product.”

“Once Listeria gets into a plant, it’s really hard to get rid of,” Marler continued. “That’s why thorough cleaning, thorough testing is important.”

Commercial Food Sanitation (CFS), an Intralox company, offers trainings, expert consulting, and in-depth programs that can enhance your team’s food safety protocols—or even build them from the ground up.

CFS’s consulting services include comprehensive assessments of your facility’s sanitation practices, identifying areas for improvement and providing tailored recommendations. Their training sessions—which range from on-site workshops to full certification pathways—equip your team with the industry’s latest food safety knowledge and skills.

CFS’s Sanitation Essentials Training, for example, offers attendees an engaging, hands-on approach to learning about wet cleaning, dry cleaning, and environmental monitoring. Taught by industry-recognized experts, these sessions begin instilling passion for food safety in your team while also ensuring their proficiency.

Programs like their Continuous Improvement Program create an extended, in-depth partnership between CFS experts and your team that’s tailored to your goals. Through in-person visits, virtual meetings, and ongoing support, they strengthen your organization’s food safety leadership while identifying how to meet your goals sustainably.

Plus, as an Intralox company, CFS can use the power of Intralox FoodSafe solutions to support your team as they learn how to reduce risk and stay ahead of industry trends.

Systemic Prevention

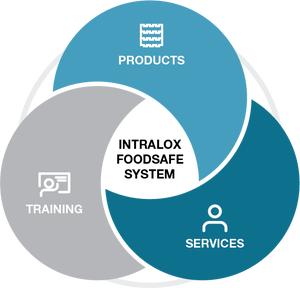

Once you’ve sharpened your team’s knowledge and skills, it’s crucial to use hygienic, fault-tolerant belting and components. We’ve reinvented our entire food product line to develop The Intralox FoodSafe System, which enables your team to maintain the highest food safety standards.

Working directly with our customers, Intralox experts evaluated more than 1,000 of their conveyor systems to understand exactly what risks and challenges they faced daily.

We used this knowledge to develop a comprehensive suite of products, services, and training that’s designed to work together perfectly. It ensures that every element of your facility contributes to a safer food production environment.

You can significantly reduce the risk of microbial contamination and protect your brand from potential recalls by operating within The Intralox FoodSafe System, which includes a range of tools and services:

- Modular plastic belting: Engineered for fault tolerance and fewer foreign material risks

- ThermoDrive technology: Improves hygienic performance and maximizes cleanability

- Clean-in-Place spray bar: Simplifies sanitation procedures and expedites debris removal

- The FoodSafe Conveyor Program: Includes comprehensive assessments, health checks, and hands-on training to optimize your conveyor systems

By using these solutions, you can proactively address potential contamination sources, maintain a clean and safe production environment, and achieve operational excellence.

Trust and Transparency

If the worst happens and you have an outbreak, there are still steps you can take to protect both your consumers and your brand.

Engaging with your customers transparently and taking quick corrective actions are essential. Unfortunately, this includes a product recall.

Once the recall becomes public, regaining customer trust and brand equity will be challenging. Your next steps must demonstrate your commitment to food safety and quality.

Intralox and CFS can support you through the process by providing expert guidance to identify the root cause, along with solutions to prevent future incidents.

A Food-safe Start to Your New Year

As we enter a new year, it’s the perfect time to evaluate your sanitation and food safety protocols. We recommend conducting a thorough review of your current sanitation practices and identifying areas for improvement. This may include updating cleaning schedules, investing in new equipment, reevaluating your environmental monitoring program, or providing additional training for your staff.

It’s never too late to implement the right sanitation measures to prevent microbial issues. By staying informed and proactive, you can protect your brand from microbial issues and ensure both your products’ and customers’ safety.

For more about how Intralox can help you protect your line, profits, and brand, visit our Intralox FoodSafe page.