Eliminate Dead Plate Performance- and Labor-related Risks

Make end-to-end transfers safely and reliably with tight transfer belting solutions

- Spotlight

- August 8, 2024

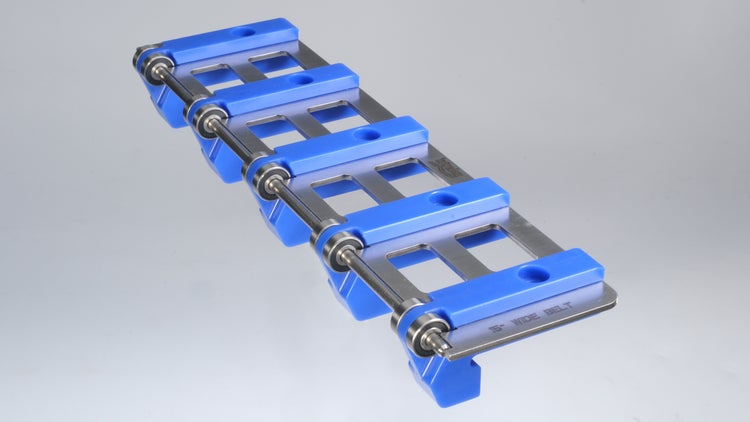

Intralox tight transfer belt systems replace dead plate and side-by-side transfers. Our modular plastic belting prevents product stranding and line jams while reducing labor and waste costs. With a smaller footprint than alternative transfers, our dead plate–free belting systems create efficiencies in your facility while maintaining your throughput targets.

Intralox Tight Transfer Intralox belts currently available:

- Series 560

- Series 570

- Series 2300 with Series 1000

Benefits

- Eliminate dead plate assembly and maintenance labor

- Streamline your facility and reduce costs

- 87% fewer customer complaints regarding dead plate impact

- Zero scraped products

Dead plate–free transfers with no tipping, stranding, or jamming

Our compact nosebar transfer units are pre-engineered and pre-assembled. This lowers your engineering and installation time by roughly 50% and eliminates guesswork in spacing, alignment, and waterfall. The units include 6-mm-diameter blue nylon nosebars for small transfer gaps and optimal wear resistance.

Benefits

- Nylon offers optimal wear resistance compared to metal or UHMW-PE materials

- Available in widths of 24 in, 36 in, and 48 in (610 mm, 914 mm, and 1,219 mm)

- Wear-resistant aluminum end caps and mounting plates