Increase Productivity at Your Can Manufacturing Plant

Three Intralox technologies that make the difference

- Insights

- December 4, 2024

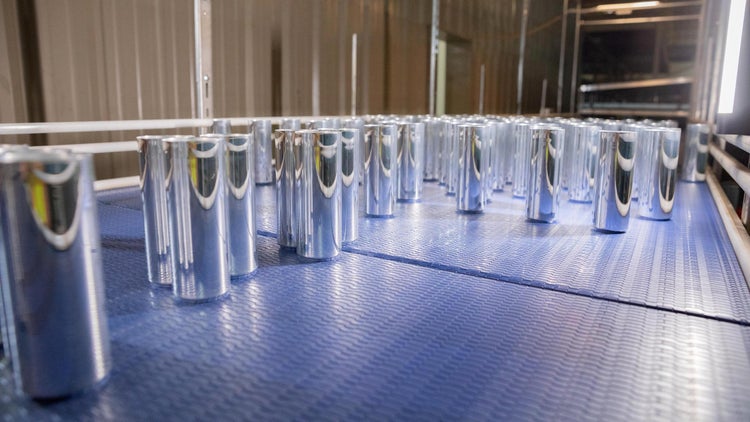

Spoilage and unplanned downtime are a consistent threat to any can manufacturing plant’s productivity and profits. Add production time lost on maintenance, along with ever-increasing demand for new sizes and labels, and it can seem impossible to meet your production goals—especially in a reasonable footprint.

As your trusted partner for solutions in the canmaking industry, Intralox is dedicated to creating innovative can conveyance technologies that optimize accumulation and efficient production while handling your products gently.

Let us introduce you to three solutions that can protect—and even increase—your line’s productivity.

#1: Eliminate Dead Plates with S570 Tight Transfer Belts

Dead plates can rip belts and cause unplanned downtime. They also damage and strand cans, increasing the labor needed to clear the line and risking mixed-label pallets. The new Intralox Series 570 Tight Transfer belting solution solves these problems, reliably increasing efficiency while easing maintenance concerns.

Benefits:

- Reduce can spoilage by 70% compared to transfers with dead plates

- Eliminate stranded cans on dead plates and the labor needed to clear them

- Reduce risk of palletizing mixed labels

- Eliminate maintenance time on hard-to-access conveyors

- Reduce skilled labor needed for dead plate maintenance

#2: Optimize Accumulation with Spiral Technology

Sufficient product accumulation on can lines is crucial for maximizing productivity. It ensures that the rest of the line can maintain production even if one part of the line fails. However, accumulation can also risk damage to your products—unless you’re working with the right equipment.

Intralox spiral technology provides a flexible, low-energy solution to increase efficiency in can-making plants. Intralox Bi-directional Spirals enable large accumulation capacity in small footprints. They also apply no back pressure, protecting accumulated cans from damage.

Benefits:

- Large accumulation capacity in a small footprint

- Lower energy cost compared to bi-directional table on mezzanine fed by vacuum elevator

- No back pressure on cans, preventing can damage

Success in the Field

Adding an Intralox spiral conveyor boosted one can plant’s overall bright can accumulation capacity. Within six months, the plant observed a 3% increase in total can output.

#3: Maximize Washer Performance and Reliability with Modular Plastic Belting

Cheaper belting solutions can seem like a win in the short term, but belt life, herringbone wear, and maintenance requirements can become costly over time—especially in your line’s can washers.

An innovation for the can industry, Intralox’s solution for can washers, Series 9000 belting, offers the longest belt life in the industry, outlasting traditional stainless-steel belts and other modular plastic can washer belt solutions. Its low maintenance requirements increase line efficiency by increasing throughput and uptime. S9000 belting also has no sharp edges, which improves worker safety and reduces spoilage.

Benefits:

- Over 3 times longer belt life than steel belting

- Significantly less wear on herringbones than steel belting

- Modular design provides minimal, easy maintenance and allows for sectional repairs if needed

- Retrofit paybacks are possible in under one year (depending on washer speed and existing operating conditions)

Conveyor Belts for Can Manufacturing

Intralox technologies solve an array of problems to make significant impacts on can plant productivity.