Intralox introduces a solution for curved conveyors

- News

- April 23, 2015

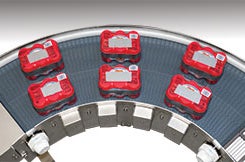

Reducing footprint while maximizing product performance, the Intralox SERIES 2100 ZERO TANGENT Radius enhances conveyor reliability and allows the freedom of engineering and manufacturing flexibility.

Intralox is the first global company to partner with equipment manufacturers to allow them to design and fabricate zero-tangent curve conveyors.

The Series 2100 Flat Top Zero Tangent Radius belt is designed specifically for curved conveyance, free of straight sections, maximizing all available space. The S2100 features a smooth, closed-top surface that can handle a variety of package sizes, types, and configurations, including delicate products (e.g., packages immediately exiting a shrink wrapper).

The new belt is able to maintain product orientation and spacing through its curves and its compact design provides flexibility, simplifying layout design and conveyor installation.

“Equipment manufacturers always talk about three things—functionality, space and price,” said Abraham Miller, Intralox Engineer. “The Series 2100, with its supported documents, exceeds these needs and is an ideal solution for both equipment manufacturers and end users alike.”

For more information, visit ZERO TANGENT Radius.