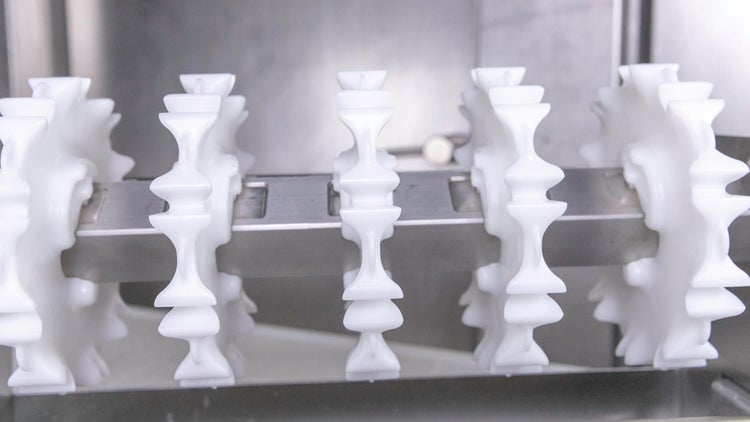

Introducing Intralox CleanLock Sprockets

Eliminate belt edge damage and FMC caused by sprocket drift

- News

- September 10, 2024

Intralox® CleanLock™ sprockets eliminate belt breakage, foreign material contamination (FMC) risk, and downtime caused by sprocket migration. An Intralox® FoodSafe™ innovation, CleanLock sprockets are designed to maintain their own alignment on the shaft without retaining components while ensuring proper belt tracking and load sharing. Plus, they’re quickly and easily installed onto a specially machined shaft—available from Intralox—using just a screwdriver.

Benefits

- Ensure proper belt tracking and drive/idle configuration to prevent belt edge breakage and FMC caused by sprocket drift

- Eliminate retainer rings, lock collars, and hose clamps for a shaft assembly that’s easier and safer to clean and maintain

- Keep sprockets aligned when cleaning with high-pressure hoses

- Eliminate safety concerns stemming from sprocket drift and positioning components