New Products: Grow Fearlessly with Expanded Intralox FoodSafe and Automation Offerings

- News

- February 20, 2024

When your brand is at stake, you need a partner you can trust. At Intralox, we focus our expertise on solving your challenges before they arise. Intralox FoodSafe solutions make foreign material contamination, pathogens, and allergen risks an afterthought. Our solutions for logistics and material handling have revolutionized the way our partners think about footprint and throughput. And now, we’re happy to share that we’ve expanded upon these products over the past year so you can continue to grow your operation fearlessly.

Learn more about new and improved Intralox products.

Belting, Equipment, and Components

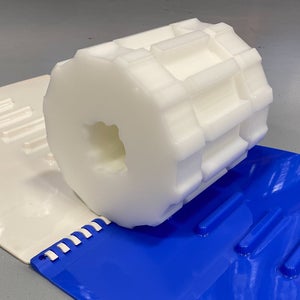

ZeroSplice Technology

Combining the hygienic properties of Intralox’s ThermoDrive belting with the self-service model of our modular plastic belting, ZeroSplice technology allows food manufacturers to easily connect ThermoDrive belting themselves with no splicing required. This increases uptime and eliminates the need to own, maintain, and use a splicer or to rely on third parties for splicing services.

SmartPath Singulator and Gapper

The new Intralox SmartPath Singulator and Gapper is the first and only machine to combine two critical automation functions into one with a single motor and one continuous conveyance surface. The smallest activation zones ever seen in the material handling market allow for more independent, precise control of difficult-to-handle package types such as polybags. And at just 8 ft (2.44 m) long, the SmartPath Singulator and Gapper requires up to 42% less footprint than competitive technology—and 60% less footprint than competitive technology when combined with the Intralox ARB Sorter S7000.

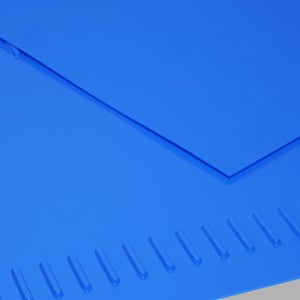

Heavy-Duty Edge for S900 Flush Grid Belts

Intralox FoodSafe Heavy-Duty Edge (HDE) belting is the most snag-resistant belting on the market, making it the best option to prevent foreign material risk. Now available on S900 Flush Grid belts in a variety of materials and colors, this combination expands the already best-in-class performance to food applications from microwaves to UV curing and more.

Learn more about the Series 900 Raised Rib Heavy-Duty Edge belt

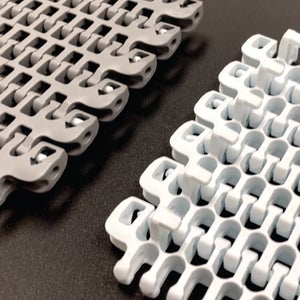

AIM Heavy-Duty Peg

This new peg allows our standard Active Integrated Motion (AIM) technology to convey products weighing up to 30 lb (13.6 kg) without risking increased wear or suboptimal equipment performance. While specifically designed to increase AIM equipment’s handling of tall or oddly shaped products like crates, boxes, and soup bags, the Heavy-Duty Peg can also be used with standard tray packs or other items. In addition to increased strength, it’s also highly cleanable, featuring an IP69K washdown rating.

Advanced Sorter Controls for ARB Sorter S7000

The Intralox Activated Roller Belt (ARB) Sorter S7000 bi-directionally sorts a wide range of products at high throughput rates. All moving parts on this “touchless” system are contained within the machine, below the conveying surface, providing gentle product handling and improved operator safety. Intralox now offers the option to include package-tracking and divert actuation logic, saving installation time and allowing users to start and stop the sorter to provide destination information for each item, increasing sort accuracy, reliability, and throughput.

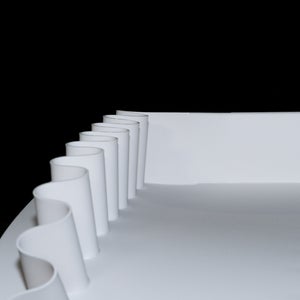

Sealed Pocket Belting

Intralox’s Sealed Pocket belting for BarDrive Series 8050 and LugDrive Series 8140 eliminates leakage and spillage. Designed to simplify food inspection, this hygienic belting uses rectangular pockets with seamless, liquid-tight seals to separate and contain your product. It lengthens belt life, lowers maintenance, eases cleaning, and improves operational efficiency over other solutions while allowing for maximum product containment with no cross-contamination risk.

Download the ThermoDrive Sealed Pocket Belt Product Highlight (PDF)

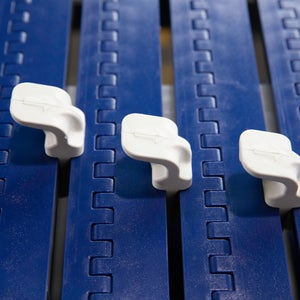

Hold Down Guides and Friction Top for S2400 Radius Heavy-Duty Edge

Our Series 2400 Radius belt with Heavy-Duty Edge (HDE) is the food industry’s most snag-resistant radius belt with the longest lasting fatigue life. Now offered with hold down guides and a Friction Top surface, S2400 HDE belting reduces downtime and extends belt life in an even broader variety of food applications.

New Sprocket Offerings for S1000 Belts

Our Series 1000’s sprocket options have expanded to include more pitch diameters and bore sizes, simplifying the process for partners seeking to standardize on S1000 while improving performance in various applications.

Groove Sprocket for LugDrive S8140 Belts

New ThermoLace-compatible groove sprockets and support wheels for LugDrive S8140 belts allow for better scraping and smoother belt operation than non-grooved drive components. This solution completely eliminates belt jumping as the lace travels around the drive sprocket.

Materials

PK Material for Food-safe Applications

Developed for direct food–contact applications, Polyketone (PK) is a robust, high-performance material that’s three times more impact resistant than acetal, plus more chemical and abrasion resistant. Now available across more than a dozen series and styles and in critical applications like tight transfer (on our S560 belting) and radius (S2400 HDE), Intralox PK minimizes foreign material risk while improving product release for increased yield and easier cleaning.

New Offerings for LugDrive S8140 Belts

The first of Intralox’s lug-driven belts, LugDrive Series 8140 expanded the ThermoDrive product line’s reliability and hygienic performance across a broader range of conveyor types. And now it’s available in several new configurations:

- Embedded Diamond Top surface in polyurethane offers improved product release

- Dura material offers the best impact resistance of our ThermoDrive line, withstanding a wide variety of extreme conditions

- Now available in white, which provides higher product contrast useful for the dairy and meat, poultry, and seafood industries

Tools and Resources

ThermoDrive Belt Puller

A simpler, faster, and safer belt-handling tool, the new ThermoDrive Belt Puller requires fewer workers for belt removal and installation. It also reduces the risk of drops that cause belt damage, foreign material contamination, and worker injury.

See our "ThermoDrive Belt Pullers" Performance Support Video

ThermoLace HDE Tools

We now offer tools to simplify the installation and removal of ThermoLace Heavy-Duty Edge (HDE). These include our Mini Needle Nose Pliers and Slip Joint Pliers with Removable Rubber Tips.

Performance Support Videos

This series of two-minute “how-to” videos addresses common belt challenges and frequently asked questions. Now with a more expansive offering of ThermoDrive technology topics, each video in this library is designed to help you install, maintain, or troubleshoot your Intralox conveyor belts and components.