What Could You Do with More Uptime in Your Plant?

The secrets to gain more and maximize the benefits

- Insights

- August 20, 2021

Think of something everyone uses that’s designed and built to move things. Got it? Whatever popped into your head, it’s probably not fulfilling its true purpose when stopped. Just like vehicles or elevators, food processing lines aren’t made to sit still. They’re intended to run.

All sorts of forces can act upon their motion—or your plant’s uptime—to cause unexpected downtime. Some are visible and obvious when they occur, like equipment breakages and foreign object incidents. But others are harder to spot, robbing your lines of efficiency.

If you could wave a wand and create more uptime in your facility, what could you do with it? The answer is plenty, and probably more than you think (no magic required).

We’ve identified two areas of opportunity to help you increase your plant’s uptime.

Maximize Your Scheduled Downtime

While scheduled downtime is certainly necessary, it’s crucial to reduce that time frame as much as possible. Here’s a handful of solutions our experts recommend.

Sanitation Efficiency

Your equipment’s hygienic design is where the battle to capture more uptime really begins. When choosing conveyors, consider equipment that offers easy access for cleaning so that sanitation crews can do a thorough job in a brief timeframe.

Darin Zehr, Commercial Food Sanitation General Manager, says that hygienic design can address other sanitation challenges as well. “Equipment that’s designed in a way that actually reduces product buildup and product loss can further minimize cleaning time. You’d be amazed how much uptime could be recaptured when you invest on the front end in building a sanitary operation.”

Intralox Team Tip: Encourage your sanitation crews to perform pre-shift meetings. Together, they can review what happened the night before and plan for the upcoming sanitation cycle.

Streamline Maintenance

When repairs or inspections are necessary during production, seconds count. Your maintenance personnel must be able to access equipment quickly and easily. Having the right tools can shave precious time off repetitive tasks and even reduce labor.

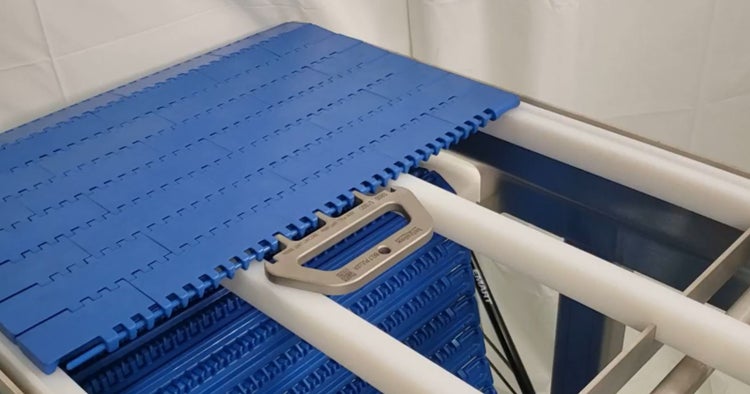

“We try to address those needs,” says Dana Summerour, Intralox N.A. Food Business Unit Commercial Leader. “For example, how can we make it easy to remove one of our belts? In that instance, we developed a specific tool that’s designed to make the process of removing a rod safe and efficient for maintenance staff when they have to open up a conveyor belt.”

Maintenance crews can make quick work of repairs and other tasks with the right tools. Pictured above, the Intralox Belt Puller.

Another way to make the most of planned downtime is by using a preventive maintenance checklist. For tips on how to start one, or to update your existing list, you’ll find some high-level suggestions in this downloadable guide.

Cross-functional Communication

If your teams communicate actively and regularly, your plant has a better chance of achieving its uptime potential. For instance, should an issue arise during production that could affect sanitation, make sure they’re aware of it so the crew can be prepared to meet the challenge.

“Coordination, especially between sanitation and maintenance, is key,” says Zehr. “How well those teams communicate and support each other can impact efficiency across the facility. A lot of plants haven’t even tapped into the potential there.”

Reduce Your Unscheduled Downtime

Usually, gaining uptime in your plant comes down to preparation. With a trained staff and a culture of food safety, you can prevent the most common issues from impacting your production window and eliminate unscheduled downtime at your facility.

Make sure your sanitation crew has accessibility to the right tools, chemicals, and training so they can work with a cadence as a unit, rather than as individuals.

General Manager, Commercial Food Sanitation, an Intralox company

Keep Sanitation Cycles on Track

Do your sanitation cycles continuously run long? If you’re drawing high swab counts or finding broken plastic after cleaning, it likely signals a larger problem. Ensuring your team has the right training to maximize efficiency is a good place to start.

“Training is key,” says Summerour. “Building partnerships within your supply chain so you can lean on their expertise for training is probably one of the best practices that we see across the board.”

We recommend working with a company like Commercial Food Sanitation to conduct an assessment at your facility. This can help you discover where efficiency can be gained. They can also provide the kind of training that will have your sanitation team operating like an F1 pit crew.

Prioritize Preventive Maintenance

The worst uptime thief is some incident that requires an unplanned production halt. From broken belts and foreign material contamination to product holds and investigations, anything that must be addressed before production continues can steal time, money, and perhaps even brand value.

Preventive maintenance is the key. In a previous article, we identified several ways food processors can apply PM practices to achieve operational excellence and food safety.

Summerour says a sustained commitment to preventive maintenance can improve performance across the facility. “Your conveyors are going to run better, your belts will last longer, and if you do have an event, you’ll be better equipped and prepared to address it and get moving again.”

Does More Uptime = Higher Throughput?

If a plant gains more uptime, does that always translate to higher throughput? What a facility might do with more uptime depends entirely on that plant and its operational goals. For example:

- Plant A is not struggling with unscheduled downtime. But they’re looking to gain uptime where no spare production time exists. In this case, more uptime may mean the opportunity to increase throughput.

- But Plant B is battling unscheduled downtime that’s impacting their uptime. If they manage to boost production time, it may simply result in their ability to meet current throughput goals. Or it could provide opportunities to make repairs, train staff, or schedule and perform preventive maintenance.

Remember that what may seem like the norm isn’t the only reality available to your plant.

Engage everyone in the shared goal of gaining uptime and keeping the plant running. Ideas that lead to significant improvements can come from anyone.

“I know of an operator who came up with a design change on a piece of equipment that cost around $10,000,” says Zehr. “It reduced each sanitation cycle by about 20 minutes, so it paid for itself after three days of production.” Imagine that effect multiplied across numerous conveyors and you’ve probably freed up several days of production time over the course of a year.

Your facility is designed to run product. Establish a culture of food safety, eliminate the forces that sabotage uptime, and your plant is sure to gain efficiency and attain operational excellence.

Contact us to connect with a food safety specialist or to learn about the services and products that can help your plant gain uptime.