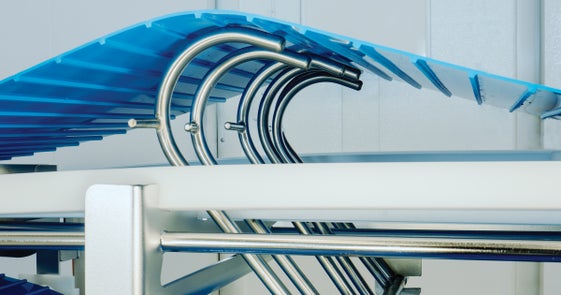

- BarDrive

Simplified, Reliable Food Conveyance

Intralox’s original homogeneous thermoplastic belting

High-load hygienic conveyor belting

Reliability and hygiene without compromise

Intralox® BarDrive™ belting helps food processors achieve the highest food safety and hygiene standards across a wide range of applications. Utilizing a full-width drive bar, BarDrive belts maximize belt pull for direct food–contact applications while ensuring a tensionless, positively driven system that’s reliable and simple to maintain.

Benefits

- Proven results worldwide across configurations

- Maximum belt pull from full-width drive bars

- Reliable performance under extreme conditions

- Easy installation or drop-in replacement

- No splicing required when paired with Intralox ZeroSplice technology

Advantages

Where can BarDrive conveyor belting deliver value for you?