Customized Services to Optimize Your Spiral System’s Performance

Intralox delivers innovative spiral conveyance technologies combined with the services of our spiral experts to create a fully customizable program that fits your specific needs. Our services portfolio includes spiral optimization, customer product testing, remote spiral monitoring, and access to the sanitation experts at Commercial Food Sanitation (CFS), an Intralox company.

Spiral Optimization

Our spiral technical group carefully analyzes each system and works to understand your specific challenges, needs, and goals. Then we deliver a customized, 100% Intralox-managed and guaranteed solution for your existing spiral system. The results of effective spiral optimization include:

- Increased throughput

- Reduced maintenance and downtime

- Improved product quality

- Extended system life

Intralox Conditioning Control Center

Our state-of-the-art Conditioning Control Center is located at Intralox’s global headquarters in New Orleans, Louisiana. Here, our spiral specialists can perform customer product testing with various foods and focus areas (such as freezing curves, airflow, product alignment, transfer, and more). Request your own test to be conducted either in person or livestreamed.

Download our Product Testing and Conditioning Control Center Service Highlight (PDF)

Conditioning Optimization Services

Conditioning Optimization—available exclusively from Intralox—helps food processors achieve maximum airflow efficiency, which increases throughput, improves product quality, enhances food safety, and reduces energy costs.

Intralox Conditioning Specialists study your spiral cooler or freezer to ensure heat transfer rates are optimized. We conduct proprietary airflow analyses and implement vital mechanical changes so your system delivers maximum efficiency, consistent product quality, and reduced energy consumption.

Remote Spiral Monitoring with IntraloxIntelligence

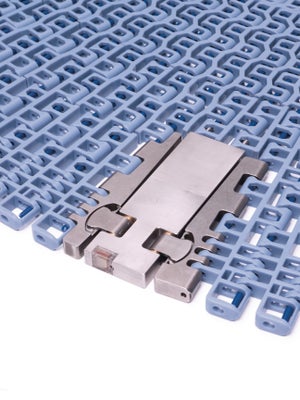

IntraloxIntelligence is a patented innovation that gives you the power to maintain optimal spiral performance with continuous operational insight.

It works using a sensor node, designed to operate in harsh process conditions, that travels along the entire belt path and captures a full profile of your spiral system. Your spiral’s tension, overdrive, and helix path temperature are monitored remotely through RFID technology.

Reduce your total cost of ownership and improve operational equipment effectiveness with this monthly subscription service that includes:

- Spiral Data Collection

- Live Data

- Diagnostic Analysis

- Recommendations and Results