Iwate Nokyo Builds Safe, Hygienic Processing Lines with ThermoDrive Belting

Case StudyIwate Nokyo

Products

ThermoDrive Belting

Industries

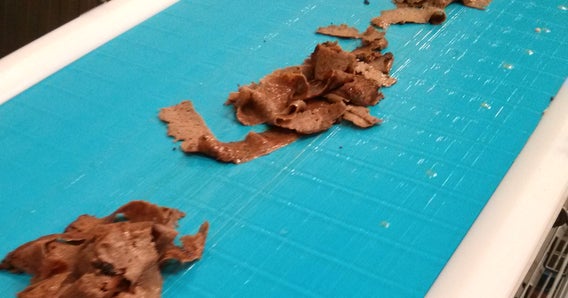

Meat and Poultry

Customer Objectives

Iwate Nokyo Chicken Foods Corporation, based in Iwate Prefecture, Japan, sells poultry products to wholesale distributors and large-volume meat resellers across Japan. Iwate Nokyo Chicken Foods’ Ken Oh plant operates on a single shift to process 63,000 chickens each day.

The highly tensioned, traditional PVC flat belting the Ken Oh plant used along its processing lines was the source of many challenges. The belts were prone to meandering, mistracking, belt fray, cracking, and slippage. This led to belt damage, shortened belt life, and conveyor frame distortion. Resolving these challenges required frequent repair and maintenance. When undertaken, repair work lasted two hours.

Our plant has the longest conveyor line in Japan. Typical conveyor lines are no more than 13-m long, so our line is three times longer than a typical line, thanks to ThermoDrive. It would have been impossible to build a line this long using PVC flat belting.

Because the flat belts were hard to clean, sanitizing them required workers to wash the belts with cloths and chemical cleaning solutions. Still, hygiene was a concern because of mold that grew on the back side of the belting, and extant risks of contamination and bacteria harborage.

Intralox Execution

Seeking a belting solution that would be efficient, hygienic, easy to use, and easy to clean, Iwate Nokyo Chicken Foods chose to install Intralox ThermoDrive belting. With ThermoDrive belting, the Ken Oh plant was able to install both horizontal and incline belting, equip conveyors with flights as needed, and use both blue and white belts. It also allowed them to build a 98.4-ft (30-m) cutting-and-trimming line, achieving a length that was previously impossible.

Results

Iwate Nokyo Chicken Foods has been thoroughly satisfied with the results of the ThermoDrive installation. All the problems the company experienced with highly tensioned, traditional PVC flat belting—including mistracking, fraying, cracking, belt wear, and frame distortion—have been eliminated. The ThermoDrive belts have proven easy to clean, maintain, and repair, and have helped increase efficiency and reduce electricity use.

Said one plant official: “Our plant has the longest conveyor line in Japan. Typical conveyor lines are no more than 13-m long, so our line is three times longer than a typical line, thanks to ThermoDrive. It would have been impossible to build a line this long using PVC flat belting.”