Namet Saves Time, Improves Product Quality with Intralox ThermoDrive Technology

Case StudyNamet

Products

ThermoDrive Belting

Industries

Meat and Poultry

Customer Objectives

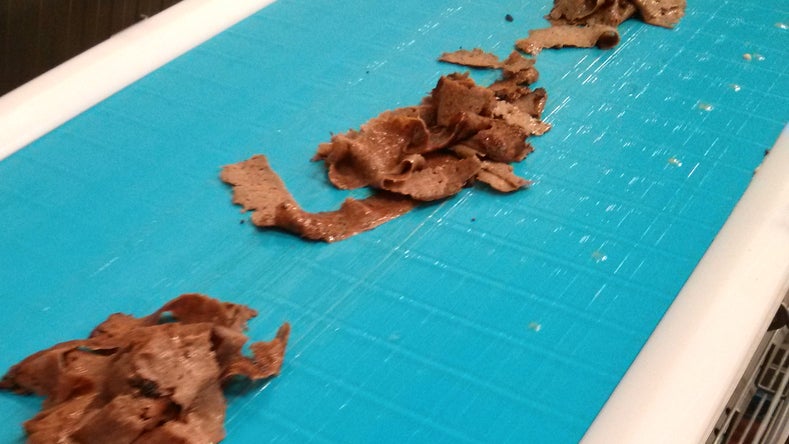

Following its increased capacity, Namet needed a permanent solution for conveying döner kebab meat. Their flat belt was not meeting the needs of the wide variety of temperatures required to produce and cool döner. Robotic applications increase the production area temperature to 85°F (30°C) and the product temperature on the belt to 150-175°F (65-80°C), and the cooling room is below freezing. The flat belt also under-delivered on the applications’ long conveyors (50-60 ft, 15-18 m): It became elongated, slipped, and required frequent replacement. Namet also wanted a shorter cleaning process that could completely satisfy their hygiene requirements.

Intralox Execution

Always aiming for better product quality and less yield loss, Namet contacted Intralox for this particular purpose. In a matter of two days, Intralox specialists presented Namet Technical Manager Mr. Volkan Yıldırım with the blueprints of a new system layout and design.

Intralox brought all the experts with knowledge or expertise who were available. In only two days, I had a layout plan and design guideline of conveyor frames including the best valued belts. Intralox has also supported us with hygienic design principles and CIP system, which help our cleaning crew as we never, ever compromise on hygiene and food safety.

Mr. Volkan Yildirim

Namet Technical Manager

The problematic long flat belt was replaced with ThermoDrive Series 8050 and 8050XT belting, which is made from homogeneous thermoplastic with 100% closed surfaces. ThermoDrive’s zero-pretension operation ensures that it is the only technology that allows loose running of the entire conveyor system at any length, resulting in extended belt life, minimized costs, reduced downtime, improved belt-edge integrity, and increased efficiency. Namet also installed the Intralox Clean In Place (CIP) System to complement ThermoDrive belting. The spray-bar system is engineered to thoroughly clean the belt underside, sprockets, and shafts.

Results

ThermoDrive belting has run smoothly at Namet since the installation. Döner quality is preserved from production through cooling with no product loss. Engagement of the CIP System provided an easy cleaning and sanitation process for the ThermoDrive belt and has significantly increased döner conveyor hygiene.

Mr. Yıldırım was pleased with the entire experience. “Intralox brought all the experts with knowledge or expertise who were available,” he says. “In only two days, I had a layout plan and design guideline of conveyor frames including the best valued belts. Intralox has also supported us with hygienic design principles and CIP system, which help our cleaning crew as we never, ever compromise on hygiene and food safety.”