New Products: Intralox Upgrades Entire Food Processing Suite

- News

- April 17, 2023

If Intralox doesn’t already have a product that addresses your operation’s pain point, we’ll invent it. For more than 50 years, we’ve turned challenges into solutions, optimizing your lines and moving your business forward. Now, as part of our relentless culture of continuous improvement, we’ve upgraded our entire suite of solutions for food processing, all while maintaining the best lead times in the business.

Learn more about Intralox’s food processing solution upgrades.

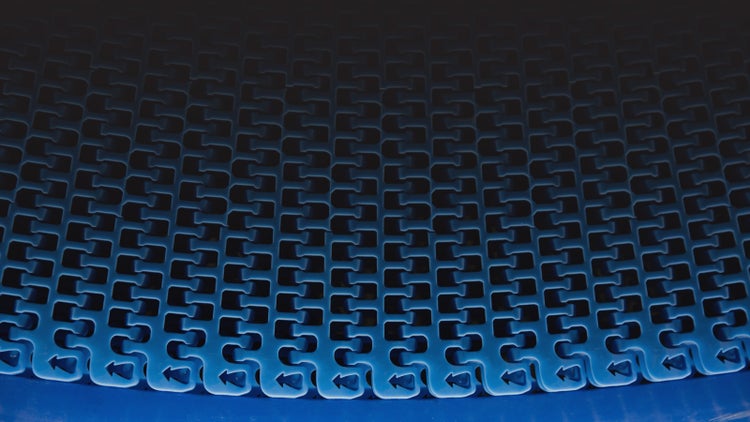

Belting and Components

2400 Radius with Heavy Duty Edge

The Intralox Series 2400 Radius belt—now available with Heavy-Duty Edge (HDE)—is the food industry’s most snag-resistant radius belt with the longest lasting fatigue life. Its innovative design is paired with our patented Load-Sharing edge (LSE) technology, reducing downtime and extending belt life by decreasing fatigue failures. A direct retrofit to legacy S2400 belts, the S2400 HDE can upgrade your existing radius without changing sprockets, designs, or drawings.

Clean Release for S800 HDE

Our S800 HDE belting is now available with Clean Release: a simple, robust stainless steel belt component designed to reduce foreign material risk. Facilitating easy opening and closing of S800 Heavy Duty Edge belts, Intralox Clean Release provides customers an intuitive, tool-free solution for use in belt removal and reinstallation without belt or rod damage.

Learn more about our tools and components for modular plastic belting (MPB)

New Components for S2300 Flush Grid Dual Turning

The unique design of the S2300 Dual Turning belt eliminates dead plates on radius applications—including S-curves—enabling standardization for all your radius conveyor needs. Intralox now offers an Edge Bearing option for the S2300 Flush Grid Dual Turning belt, along with a Mold to Width (MTW) option. Edge Bearing allows the belt to run at higher speeds and minimizes pressure velocity impact. MTW Flush Grid Nose-Roller Dual Turning belting meets radius applications that require S turns or for the belt to turn both right and left within the same conveyor.

50-mm Sideguard and Lane Divider for Side Drive S2700

Furthering Intralox’s goal of expanding our S2700 Side Drive offerings, this 50-mm version of the S2700 sideguard and lane divider provides twice the containment volume of our existing component. The upgrade allows its use in buffering applications—such as pasta production—with many applications likely to follow.

Materials and Styles

Embedded Diamond Top for ThermoDrive S8140

Our hygienic, lug-driven ThermoDrive S8140 belting is now available in polyurethane with Embedded Diamond Top surface, which drastically improves product release, reducing product waste and buildup. A drop-in replacement on many existing single-lug belting applications, S8140 belts require no conveyor retrofits or redesigns. Their smoother lugs offer enhanced hygiene, and a dual-lug option is available for conveyors in widths of 30–60 in (76.2–152.4 cm).

A23 for ThermoDrive

Intralox now offers ThermoLace S8050 and S8140 belting in A23 material, with S8140 also now available in White A23. Designed to overcome the challenges of warm, damp conditions in food processing, A23 significantly extends belt life along snack incline-to-packaging conveyors, making it ideal for highly seasoned products like hot, spicy, or acidic snacks or chips. ThermoLace belting offers a hygienic belt joining option that is easy to disassemble and reassemble for customers requiring belt removal for sanitation.

S560 Style and Material Extensions

Further expanding its portfolio of materials, styles, and colors, Intralox S560 Tight Transfer belting is now available in Detectable Metal X-Ray (DMX) material with Flat Top surface and PK (Polyketone) with Flush Grid or Flat Top surface. Optimized for detection by metal or x-ray detector, DMX material was developed for food processing lines that use a detector to ensure foreign material contamination does not occur. Created for direct food contact applications, PK is a robust, high-performance material that is more impact, chemical, and abrasion resistant than acetal.

Detectable PK for S1100 FT

Already available for S800 HDE and S1800 Flat Top belts, our X-Ray Detectable PK material is now offered as an option for the S1100 Flat Top belt. A lightweight alternative to acetal that’s more impact, chemical, and abrasion resistant, Intralox PK helps reduce nonmechanical belt-related foreign material in your facilities and improves release and yield in certain applications.

Download our Intralox FoodSafe Detectable Belting Product Highlight (PDF)

Tools and Resources

Rod Remover

The new Intralox Rod Remover reduces the risk of damage to belt edges or rods—as well as related foreign material risks—during rod insertion or removal. Usable in either the carryway or returnway, it ensures quicker rod removal and less downtime during maintenance and sanitation. It’s best used in conjunction with our Belt Puller.

Performance Support Videos

In an effort to grow knowledge and address common belt challenges, Intralox launched our Performance Support Videos, a series of two-minute “how-to” videos that address frequently asked questions about our belting. Now featuring ThermoDrive technology, each video in this library is designed to help you install, maintain, or troubleshoot your Intralox conveyor belts and components.

CalcLab

CalcLab, Intralox’s new web-based engineering platform, provides you with a single location for the latest calculators available. CalcLab offers a unified space for Intralox to deliver and you to perform engineering analyses with confidence while leveraging Intralox engineering expertise. CalcLab runs in the browser, so you can access it from any internet-connected device without installing any additional software.

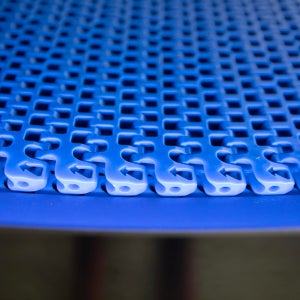

Intralox FoodSafe Conveyance Handbook for MPB

After assessing more than 1,000 conveyors, we determined that conveyor design/setup and belt handling are the leading causes of premature belt wear, breakage, and foreign material. To better facilitate the design process for end users and OEMs—as well as aid in minimizing belt breakage, foreign material risk, downtime, and throughput loss—we developed the Intralox FoodSafe Conveyance handbook. Customized specifically for direct food contact applications in poultry, beef and pork segments, it shares our optimal food safety and operational performance principles.

For a copy of the handbook, contact Intralox Customer Service