Helping You Stay Efficient and Food Safe

These tools and components can help you efficiently install, maintain, and operate Intralox conveyor belts. Developed by our conveyance and food safety experts, they are specially designed to help you maximize efficiency and minimize foreign material contamination in your facilities.

Tools

Belt Puller

The Intralox Belt Puller simplifies conveyor belt handling to ensure faster, safer installation and maintenance. Built from solid metal, this ergonomic solution enables a smaller number of workers to install or remove large sections of belting by providing a safe way to pull belts onto a conveyor.

Belt pullers can be used in either the carryway or returnway to reduce the risk of injury or belt damage. They also allow you to secure the belt in an open position on the conveyor frame for easier access during cleaning and maintenance.

Compatible with Intralox S800 and S1800 belts

Rod Remover

The Intralox Rod Remover reduces the risk of damage to belt edges or rods—as well as related foreign material risks—during rod insertion or removal. Usable in either the carryway or returnway, it ensures quicker rod removal and less downtime during maintenance and sanitation.

Compatible with select Intralox S800 belts

Components

Clean Release

Intuitive and tool-free, the Intralox Clean Release system facilitates removal and installation of Intralox S800 Heavy-Duty Edge belts. Featuring stainless steel construction, it helps eliminate belt edge and rod damage, thus minimizing foreign material risk.

Compatible with Intralox S800 Heavy-Duty Edge belt

Drive Optimization

The Drive Optimization program is a complete solution comprising everything you need to properly set up your drive system, including shaft, shaft setup CAD drawings, sprockets, sprocket spacers, and retainer rings. This solution makes drive and idle setup easy and helps prevent belt-damaging sprocket migration, foreign material risk, and downtime.

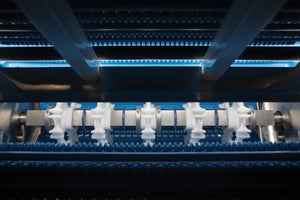

EZ Clean

Intralox EZ Clean™ components are designed to help you meet the highest hygiene and cleaning standards. The EZ Clean-in-Place System maximizes the cleanability with a custom-engineered spray pattern for complete sanitation efficiency. Angled EZ Clean sprockets allow access to 100% of the critical belt underside for total belt sanitation.