Bring It All Together, Smartly

Automate product merging from multiple infeeds using pegs instead of rails

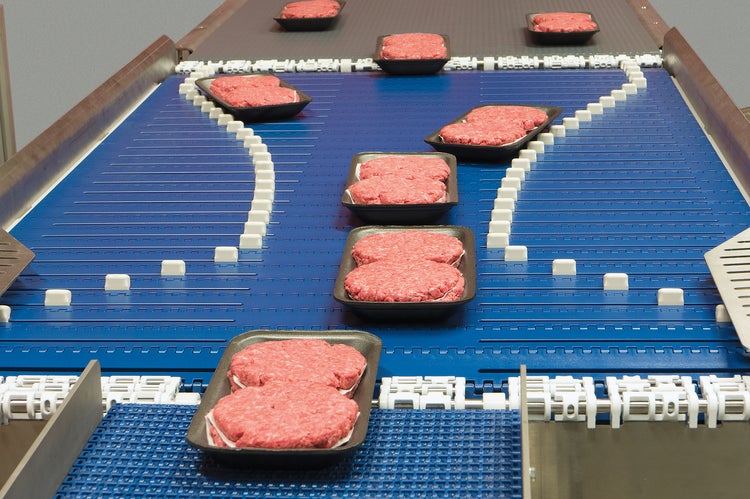

Hygienic merging conveyors

Merge products gently at speeds of up to 200 ft (61 m) per minute while eliminating jams, product damage, and contamination risks.

Intralox Active Integrated Motion (AIM) Merges deliver faster throughput and gentler product handling than fixed rails, pusher arms, or conventional labor. Moving pegs minimize blunt impact to protect the quality of your product. Gentle product handling improves product integrity, minimizing damage even when running at high speeds. AIM technology helps you increase throughput while maintaining flexibility in your lines.

AIM Merges enhance performance across your line, especially in these applications:

- Infeed to high-speed sealers

- Outfeed merge for tray-forming equipment

- Product forming and packing lines

- Spiral freezer outfeed

- Inline weighing equipment

Designed for a washdown environment, AIM belting’s single-sculpted and robust design allows for easy cleanability in critical merging areas.

With the Intralox AIM equipment, we can actually utilize 30% less staff compared to a conventional system.

Eloy Búa Iglesias

Director of Avigal’s Cambados Plant

Benefits

Processors that adopt AIM merging technology realize many key benefits, including:

- Improved cleanability

- Increased throughput

- Gentle product handling

- Improved line flexibility

- Decreased safety concerns and risks

Equipment Options

Which solution is right for you?