Switch to Superior Technology

Gentle, automated switching divides lines while maintaining product integrity and orientation

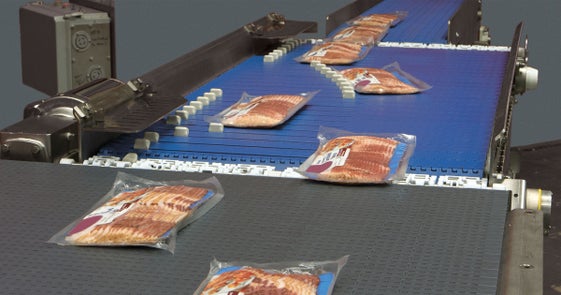

Hygienic lane switching conveyors

Switch products up to four times faster than standard pusher, paddle, and mechanical arms without the challenges of metal slat switches.

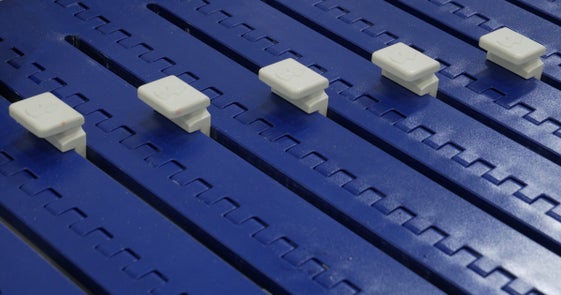

Intralox Active Integrated Motion (AIM) Switches gently divide lines while maintaining product integrity, styling, and orientation. Their reliable, automated performance helps packagers and food processors reduce labor dependence. Ideal for sealer infeeds, the AIM Switch’s moving pegs allow for a gentler product handling experience, eliminating the blunt impact that can occur with fixed rails or pushers. Designed for a washdown environment, AIM belting’s single-sculpted and robust design allows for easy cleanability in critical switching areas.

The AIM solution provides the ultimate guarantee for meeting our automatic packaging efficiency goals and reaching 100% productivity.

Christophe Verdier

Madrange Industrial Project Manager

Benefits

Plants that adopt AIM Switch technology realize many key benefits, including:

- Increase throughput rates to match other parts of the line

- Eliminate package jams, drag, and misalignment

- Requires no lubrication, minimizing contamination risk

- Handles products gently with no fixed rails needed

- Reduce labor dependence for rework

Equipment Options

Which solution is right for you?