Driven by Friction and Expertise

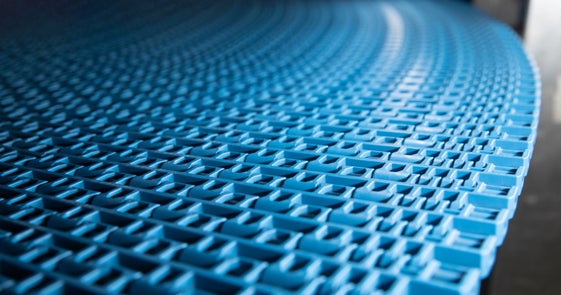

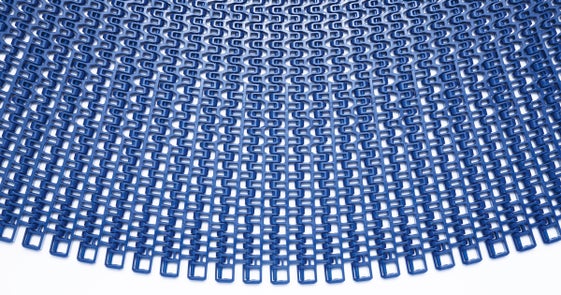

Modular plastic belting options for friction-driven spiral systems

Low-tension spiral conveyor belts

The benefits of modular plastic belting, optimized for friction-driven spirals.

Intralox modular plastic spiral belts help customers optimize friction-driven spiral conveyors for applications like proofers, coolers, and freezers. A lightweight alternative to metal belts, Intralox belts are more durable, more reliable, and easier to maintain and repair. Our dedicated team of spiral experts can help you determine the right solution to meet the needs of your product, industry, application, and plant.

Intralox optimized our old spiral equipment and installed their modular plastic spiral belting which helped us solve all the issues we were facing with our old wire mesh belts. With their products and services, they have provided us with a solution that truly meets all our production objectives.

Eiji Nohara

General Manager of Processed Food – Business Division at Marui Shokuhin

Benefits

Intralox’s belt solutions for friction-driven spirals provide key benefits, including:

- Longer belt life with less belt wear

- Simplified cleaning, maintenance, and repairs

- Lighter weight than metal belt solutions

- No metal work like cutting, grinding, or welding required

- Reduced risk of product loss or contamination

Advantages

Where can an Intralox friction-driven belt deliver value for you?