Withstand Food Production’s Harshest Environments

ThermoDrive belting is available in a variety of high-performance materials. From extreme temperatures and humidity to impact and chemical resistance, we offer material options that stand up to your facility’s toughest demands.

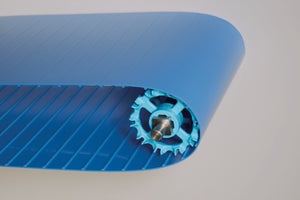

Polyurethane

Our standard option for ThermoDrive belting, polyurethane resists abrasion and wear in environments not prone to hydrolysis. Available in blue or white, it’s used in continuous temperature ranges from 20°F to 140°F (-7°C to 60°C).

Dura

ThermoDrive Dura offers the highest belt pull rating available for positive-drive, tensionless, flighted belts. The impact resistance of Dura increases belt and accessory life, minimizes downtime, and protects against foreign material contamination in high-load and/or sub-freezing conditions. Rated for continuous use from -4° F (-20° C) to 140° F (60° C), Dura delivers longer belt-life where the belt core temperature is subjected to swings from the low end of the range in operation, to the higher end during downtime and/or sanitation.

Cold Use

Our Cold Use belting brings ThermoDrive technology’s hygienic advantages where the belt is constantly exposed to ultra-cold applications. Designed to withstand the challenges food processors face in sub-freezing conditions, this belt ensures unmatched hygienic and operational performance for continuous core belt temperatures as low as -30°F (-34°C). It can be fitted with flights and/or Synchronized Sidewalls, or simply troughed for product control on incline applications.

Download our ThermoDrive Cold Use Material Product Highlight (PDF)

A23

Designed to overcome challenging food processing conditions, A23 significantly extends belt life along snack incline-to-packaging conveyors. Hydrolysis-resistant in warm or hot, humid environments, it’s an ideal solution for highly seasoned products like spicy or acidic snacks or chips. ThermoLace belting offers a hygienic belt joining option that is easy to disassemble and reassemble for customers requiring belt removal for sanitation.

HTL

ThermoDrive High Temperature and Heavy Load (HTL) material performs in applications that require loads up to 1,056 lb/ft (1,572 kg/m). It provides for continuous operation—with superior belt-pull capabilities—at temperatures between 60°F–210°F (15°C–100°C).