Endless Reliability: New Products to Enhance Your Line’s Performance

- News

- February 17, 2025

Intralox solutions bring reliable performance to our partners all around the world. To some, that means less downtime or maintenance. To others, increased throughput or gentle handling of a specific, delicate product line. To many, it’s something in between—or all of the above. That’s why our experts continuously improve our products and invent new ones. We challenge what’s possible in conveyance, proactively addressing your industry’s needs with one goal in mind: keeping you running every possible application or environment.

Learn more about our new and improved products.

Belting, Equipment, and Components

Introducing CleanLock Sprockets

Intralox CleanLock sprockets eliminate belt breakage, foreign material contamination (FMC) risk, and downtime caused by sprocket migration. Designed to maintain their own alignment on the shaft without retaining components, CleanLock sprockets ensure proper belt tracking and load sharing. Plus, they’re quickly and easily installed onto a specially machined shaft—available from Intralox—using just a screwdriver.

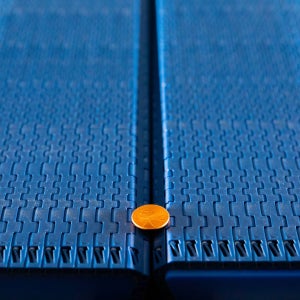

ZeroSplice Technology Expands: Now Available for All ThermoDrive Belts

With the release of ThermoLace Heavy-Duty Edge (HDE) for ThermoDrive Series 8026 belting, ZeroSplice technology is available on every belt in Intralox’s ThermoDrive product group. Combining ThermoDrive belting’s hygienic properties with our modular plastic belting’s self-service model, ZeroSplice technology allows food manufacturers to easily connect ThermoDrive belting themselves without splicing. This increases uptime and eliminates the need to own, maintain, and use a splicer or to rely on third parties for splicing services.

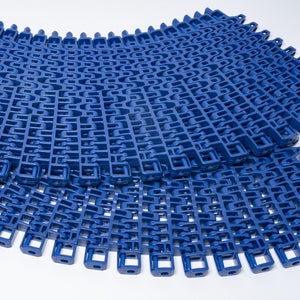

Introducing S570 Tight Transfer Belting

For operations seeking to eliminate dead plates, Intralox Series 570 Tight Transfer belting’s nosebars allow for the smallest possible transfer gaps. Shown in field testing to reduce spoilage of 12-oz sleek cans by 70% compared to dead plate transfers, our Tight Transfer belting also prevents cans from becoming stranded on dead plates. S570 Tight Transfer belting provides flexibility for the future, conveying your full range of empty aluminum containers without requiring adjustment between runs. Plus, it reduces both cost and footprint, eliminating the need for side-by-side transfers.

AIM Glide Update: Equipment Now Offered Directly from Intralox

AIM Glide is a gentle, hygienic automation solution for food manufacturers that eliminates unscheduled downtime and jams. Compared to metal slat switches, it reduces maintenance by 75% and requires 50% less cleaning time. AIM Glide does not need lubrication, and it requires no rework labor to clear jams and realign products. The solution’s belting and equipment are now both supplied directly by Intralox, improving both cost and lead time.

See how AIM Glide helped Franz Bakery eliminate unscheduled downtime

Introducing S2900 Curved Top Spiral Belting

Part of our revolutionary DirectDrive System, Intralox Series 2900 Curved Top belting brings exceptional product release to spiral freezing, cooling, and proofing applications. The belt’s surface design enables smooth transfers, and its lack of chordal action optimizes scraper placement to release challenging products such as fish, poultry, or raw dough.

Download the Series 2900 Curved Top spiral belting product highlight

Materials

Synchronized Sidewalls in Dura: More Belt Options

ThermoDrive BarDrive Series 8050 Synchronized Sidewall (SSW) and LugDrive Series 8140 SSW belts are now available in Dura material, providing optimal incline-to-packaging solutions for frozen-food applications. ThermoDrive Dura offers the highest belt-pull rating on the market for positive-drive, tensionless flighted belts—and the most impact resistance in the ThermoDrive line. It increases belt and accessory life, operates reliably across a broad temperature range (0°F to 210°F [-18°C to 100°C]), minimizes downtime, and protects against foreign material contamination. The material’s introduction to these two belts gives frozen food processors a more reliable, self-contained belt solution for bar- or lug-driven belting in colder temperatures.

Tools and Resources

Performance Support Videos

This series of 2-minute, “how-to” videos addresses common belt challenges and frequently asked questions. We recently added an overview for our Belt Replacement Ruler, and we’ve made improvements to a few inspection and installation videos. This video library is updated often to help you install, maintain, or troubleshoot your Intralox conveyor belts and components, so check in if you’re looking for a quick instructional.