- ThermoDrive Belting

Reliable, Predictable, Food Safe

The most advanced belt system for hygienic food processing

Thermodrive Hygienic Conveyor Belts

Achieve the highest food safety and hygiene standards

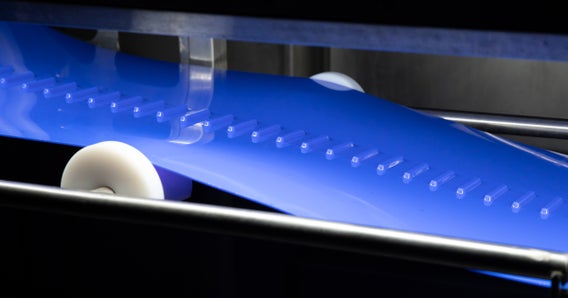

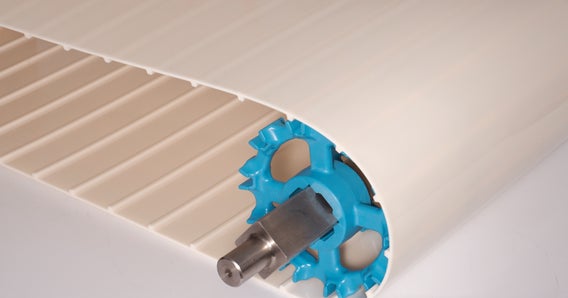

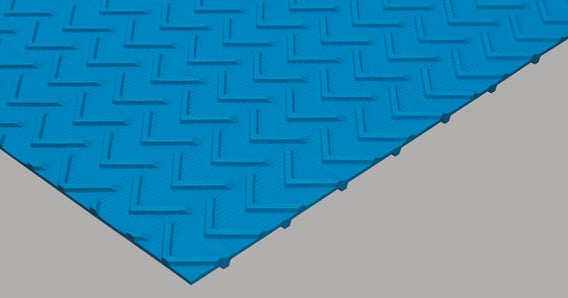

Across all belt types and drive styles, Intralox® ThermoDrive® technology combines the reliability of our modular plastic belting with the superior hygiene of a solid thermoplastic structure. Lightweight and easy to install across food processing applications, the ThermoDrive belting system eliminates tensioning, improves tracking, and mitigates the foreign material contamination (FMC) issues that often arise with traditional tension-driven belting.

ThermoDrive technology’s patented tensionless, positive-drive system:

- Extends belt life vs. competing technologies

- Halves cleaning time and water consumption

- Minimizes food safety risks

- Reduces product loss and carry-over

- Eliminates belt issues caused by tensioning or fabric

- Lowers total cost of ownership

Compared to competing technologies, ThermoDrive belting delivers 5 to 6 times the belt life and doesn’t require regular tensioning and tracking, which results in reduced cost of ownership.

Chris Wilkinson

Project Engineer at Birds Eye–Lowestoft

Belt TypesSolutions to match your conveyor drive style

ZeroSplice

Intralox ZeroSplice technology enables food processors to connect sections of our ThermoDrive belting quickly and easily without field splicing.

Options and ConfigurationsSuperior hygienic performance without compromise

Solution SpotlightZeroSplice Technology

This reliable alternative to field splicing enables food processors to connect sections of ThermoDrive belting quickly and easily without field splicing.

Download Our ThermoDrive Engineering Manual

For more information about the ThermoDrive system, including belt styles, materials, and components, download the ThermoDrive Engineering Manual.